Specialized Lab and Technical Support

Professional, efficient, and global one-stop provider for testing, analysis and R&D services.

The Kaifa R&D and Central Lab (Analysis and Testing Center) was established in 1992 and successfully obtained CNAS qualification in 2003. In addition to the laboratory in Shenzhen, we have opened additional laboratories in our branches in Dongguan, Suzhou, Huizhou, Guilin, Malaysia, Thailand, and other places. We provide services for consumer electronics terminal products, memory storage devices, semiconductor chips, medical devices, smart metering products and other industries. We have capabilities that span the four major fields of general testing services, engineering services, management systems and technology R&D. We have a large team of experienced scientific research technicians. 21% of our employees have a doctorate or masters’ degree, 29% are undergraduates, and various testing employees account for the other 50%

General Testing Services

Covers the five major fields of electronic product manufacturing process analysis:electrical performance testing analysis, material testing analysis, physical machine analysis, and reliability analysis.

1. Electronic Product Manufacturing Product Analysis: provide testing services that include visual inspection, X-Ray and CT testing, C-SAM, solder joint cross section, etc., inspect quality throughout the entire process starting from raw materials and going on to PCBA.

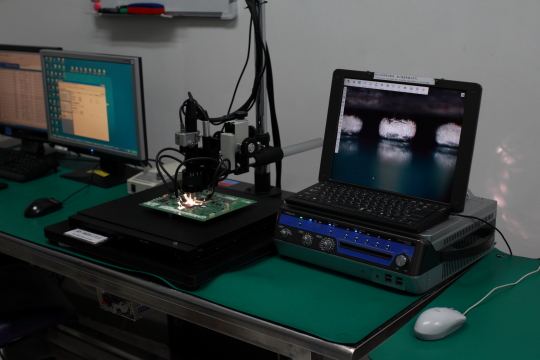

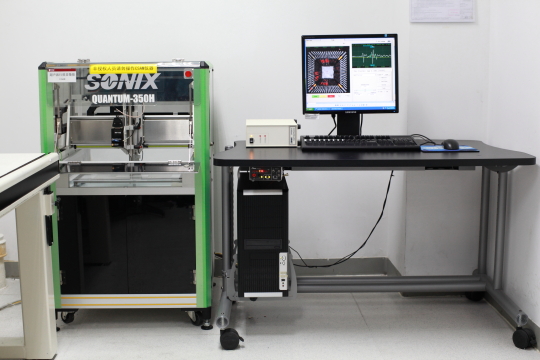

3D BGA Microscope Testing X-Ray Testing

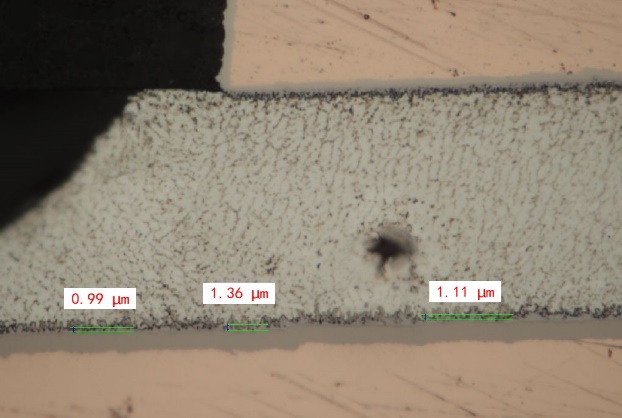

C-SAM Testing Solder Joint Cross section Analysis

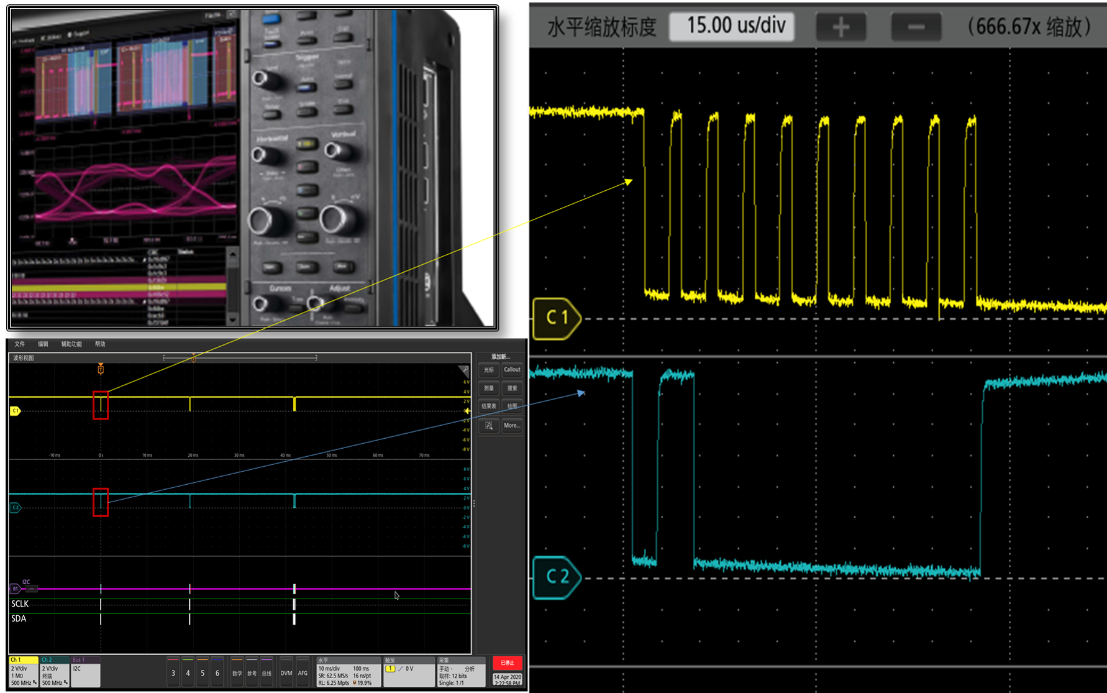

2. Electrical Performance Testing Analysis: check signal integrity / component electrical performance parameters with professional equipment.

Electricalperformance testing

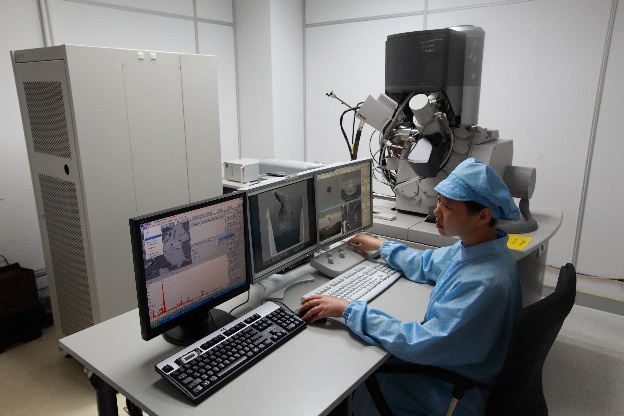

3. Material Testing Analysis; focus on various types of tests and analysis of electronic product materials, including performance analysis, composition analysis, surface morphology and element analysis for polymer materials, metal materials, energy storage materials, and testing for toxic and harmful substances in materials.

FIB& Micro-circuit Analysis Organic Volatile Species, Content Detection and Data Analysis

FTIR Testing Analysis Ion Concentration Testing

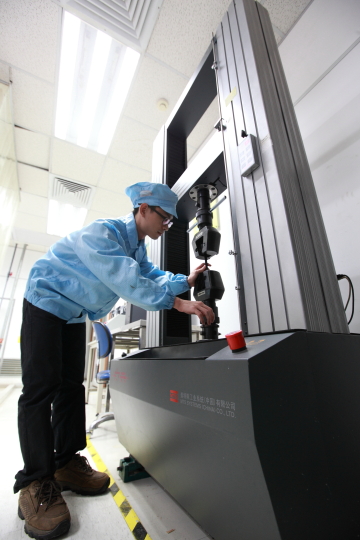

4. Physical machine analysis; focus on the mechanical characteristics of the material testing and evaluation, strain gauge analysis.

Online strain gaugetesting

Universal Material Tester

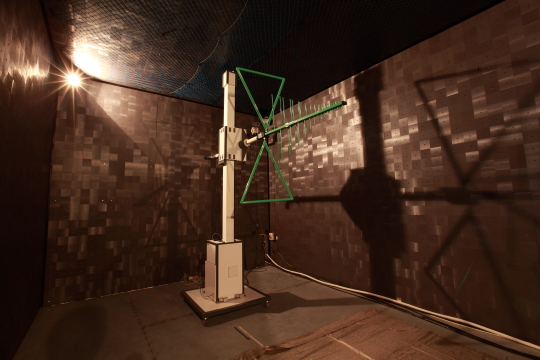

5. Reliability analysis: provide reliability testing for the four major areas of electromagnetic compatibility, environment, safety regulations and durability to assess the reliability of various different types of products.

EMC test Temperature&Humidity Test Chamber(Step-in)

Thermal Shock Test Chamber Shock & Bump test

Engineering Services

We provide product-based customized engineering technical support and services that include CAE simulation and verification, reliability engineering, product certification support, manufacturing environment control technology, process evaluation and optimization, material evaluation, and failure analysis.

Management System

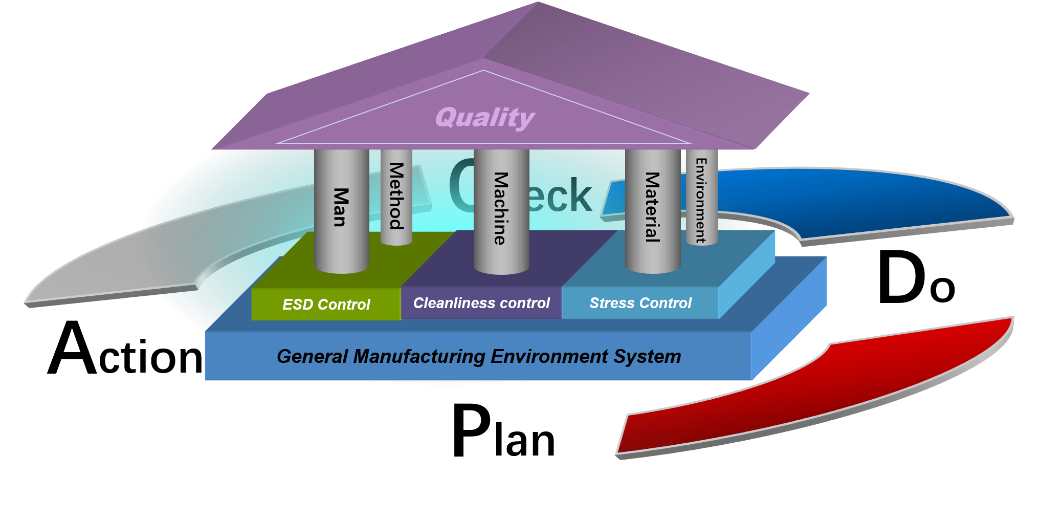

We have 35 years of experience in electronic product processes management and control. We have conducted process environment system architecture in accordance with ANSI / ESD S20.20, ISO14644, IPC9704 and other authoritative industry authoritative systems and standards. Adhering to PDCA management philosophy, it implements comprehensive management and control and uses smart systems and big data analysis methods to make up for the shortcomings of traditional ESD management and control systems to provide better protection for product quality.

Technology R&D

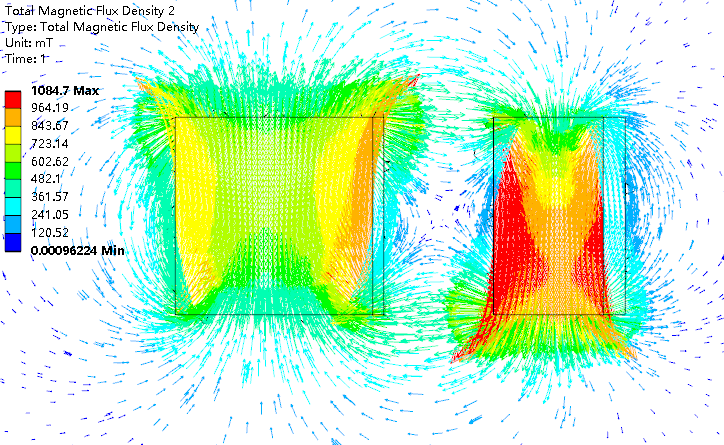

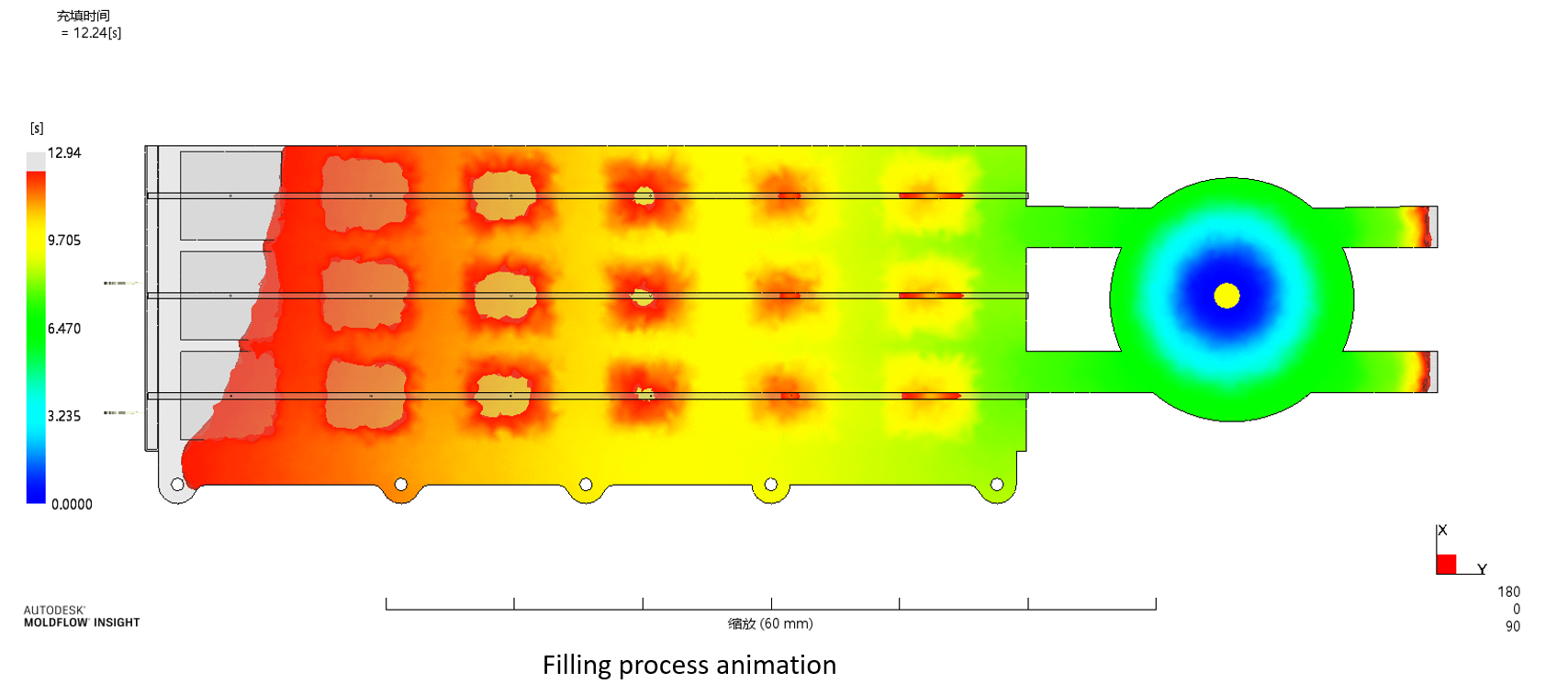

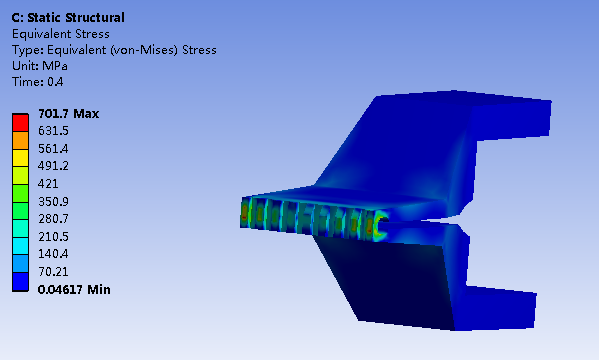

We provide technical support JDM and R&D for chip-level, PCBA level and assembly level electronic assembly technology that includes mold flow simulation analysis, welding process simulation analysis, welding head design, etc.

Static magnetic field analysis

Welding process simulation analysis

Mold flow simulation analysis

Weld head design