Analysis & Testing Center

Kaifa analysis and testing center serves the consumer electronic terminals and components industry, memory storage products industry, semiconductor chip industry, medical device industry, intelligent metering industry. Focus on material analysis and testing, SMT defect diagnosis and solution, production process control data collection and analysis, production process innovation and improvement, product reliability testing and evaluation. In the ESD electrostatic control, micro dirt control and clean production overall solution, mechanical vibration and resonant test analysis, stress and strain test analysis, SMT defect diagnosis and other fields in the industry top level.

q Material Analysis

q Failure Analysis

q Reliability Engineering

q Analogue Simulation

Material Analysis

The material analysis lab passed certification of CNAS (China National Accreditation Service for Conformity Assessment). Kaifa has the capabilities material analysis below:

q Analysis of surface micro-topography, micro-structure characterization and material composition identification.

q Composition analysis and identification of micro-contamination.

q Detection of substance of RoHS/REACH

q Physical-chemical properties analysis and heavy metal detection for wastewater and sludge

q Contamination detection of electronic products

q Detection of drinking water index

q Detection of air quality

q Testing and certification of materials’ mechanical parameters

Failure Analysis

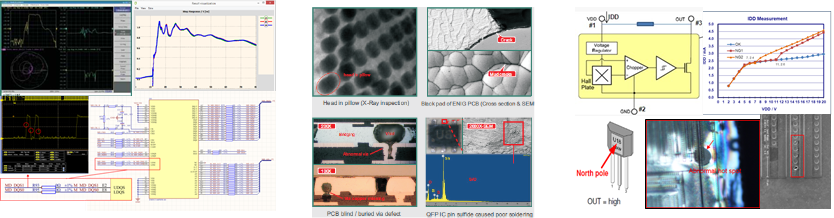

Failure analysis is one of the important means to improve product quality and reliability. We have a complete ability to analyze the failure mechanism at multi-level and multi-aspect for the weakness of the product. The FA covered mechanical, electronic, thermal, material, and chemical, etc.

q System level failure location and FA

q Assembly process failure analysis

q Component failure analysis

q Material failure analysis

System Level Signal Analysis Assembly Process FA Component FA

Reliability Engineering

Design For Engineering (DFR)

q I Phase – Concept and Target: Output below items based on PFD/CTQ tools.

Ÿ Confirm design scheme and target

Ÿ Reliability target, include parameters of thermal, EMC, structure and safety regulation

q D phase – Definition and Analysis: output below based on Reliability block diagram, Reliability allocation, DFMEA, FRACA, etc. tools

Ÿ Reliability model

Ÿ Reliability prediction

Ÿ Reliability analysis for sub-system and components

Ÿ Reliability general design

Ÿ Preliminary plan of DFMEA, and FRACAS

q O phase – Optimization and Test: Finish the items below based on Robust, ALT, HALT, DFMEA, FRACAS, etc.

Ÿ Design optimization by thermal and mechanical stress analysis

Ÿ Reliability test plan and mechanical, EMC, and safety regulation test plan

Ÿ Update DFMEA and finish the FRACAS

q V-phase – Verification and Evaluation

Ÿ Finish the reliability test and verification, finish the test of mechanical , EMC and safety regulation

Ÿ Update DFMEA

Ÿ Finish report of FRACAS

q MP phase – Reliability test for mass production

Ÿ ORT (Ongoing Reliability Test)

Ÿ Sampling test of reliability

Reliability Engineering Service

q Making reliability test plan and data analysis

Ÿ Test parameters design based on standards

Ÿ Environmental, EMC, Safety, and durability test,

Ÿ Data analysis

q Verification of reliability and lifetime

Ÿ MTBF prediction

Ÿ MTBF test plan

Ÿ Evaluation and verification of products 'lifetime

q Verification of design finalization

Ÿ Verification test plan

Ÿ Improvement suggestion and reliability growth

q Manufacturing reliability analysis and evaluation

Ÿ Verification test plan for process reliability

Ÿ Quality test, reliability evaluation/improvement of solder joints

Ÿ Mechanical reliability analysis/improvement

q EMC design and optimization

Ÿ EMC design

Ÿ Solution of EMC issue

Ÿ Prequalification service of EMC

q Training and consultant of reliability engineering

Ÿ Process reliability solution

Ÿ Components selection and reliability analysis

Ÿ EMC design and optimization

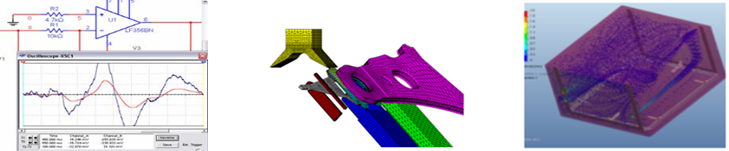

Computer Aided Engineering

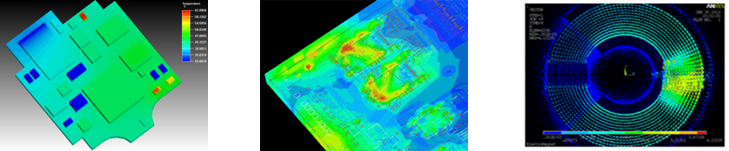

ANSYS Multi-physics

q Providing structural, thermal, fluid, electromagnetic, and coupling analysis

q Providing parameter-based modeling and design optimization

ICEPAK

q Providing electronic thermal management

q Designing heat sinks, fans, and flow layouts

MATLAB

q Engineering calculations

q Systems modeling

Electronic Circuit Mechanics Fluid Mechanics

Thermal Physis Electromagnetic Compatibility Eletromagnetism

Thermal Physis Electromagnetic Compatibility Eletromagnetism